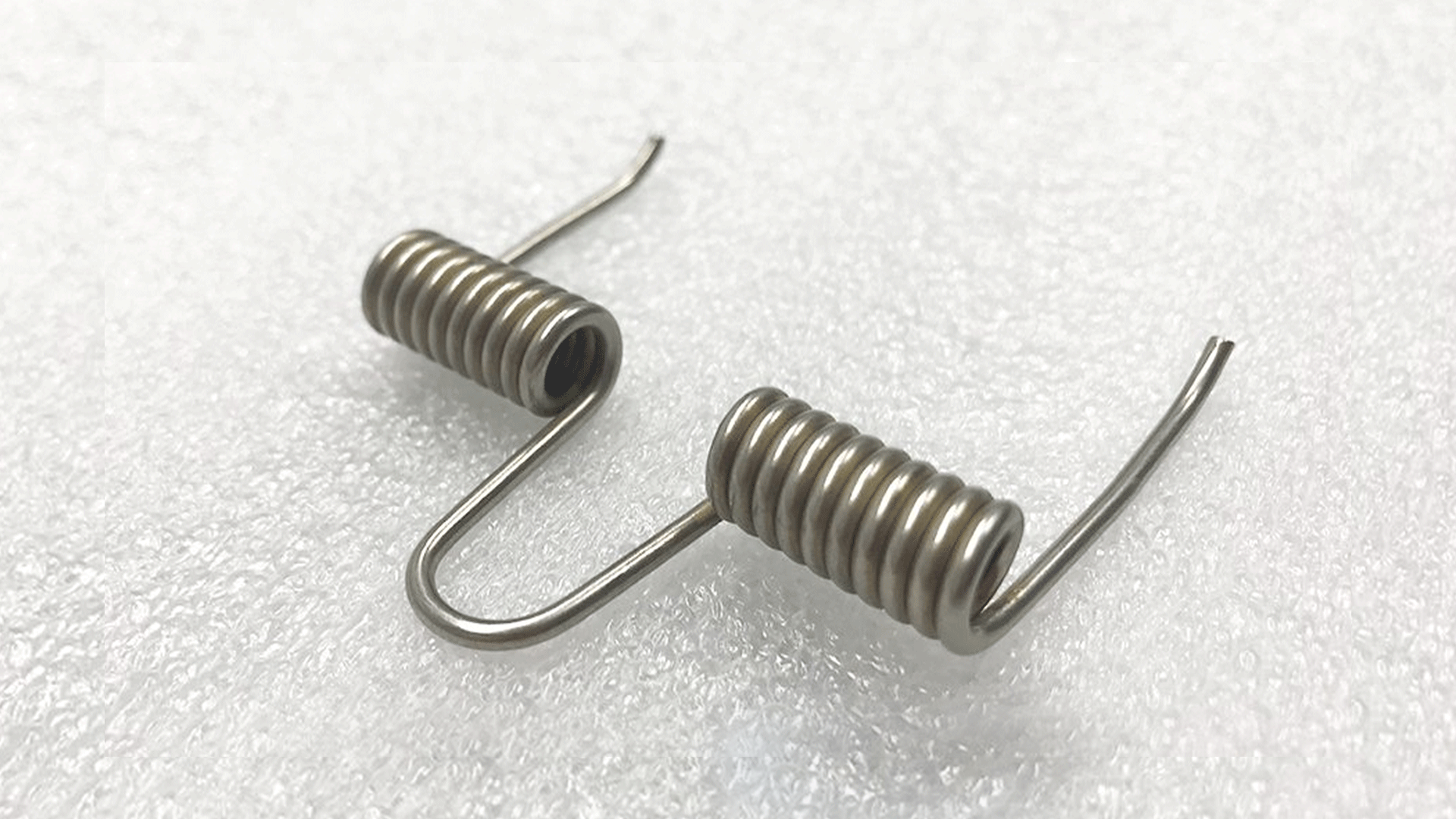

Torsion Spring

A torsion spring is a spring that works by twisting its end along its pivot; that is, an adaptable flexible item that stores mechanical energy when it is curved. At the point when it is bent, it applies a force the other way, relative to the sum (angle) it is turned.

Product Description

Uses of torsion spring:

- These are used in household purposes, like in clothes pins, clipboards and etc.

- It is also very uselful in garage doors.

- Also helpful for all the mechanical dvices such as car shocks, watches in coil springs and etc.

- Construction components also need torsion springs

- Very useful in robotics too.

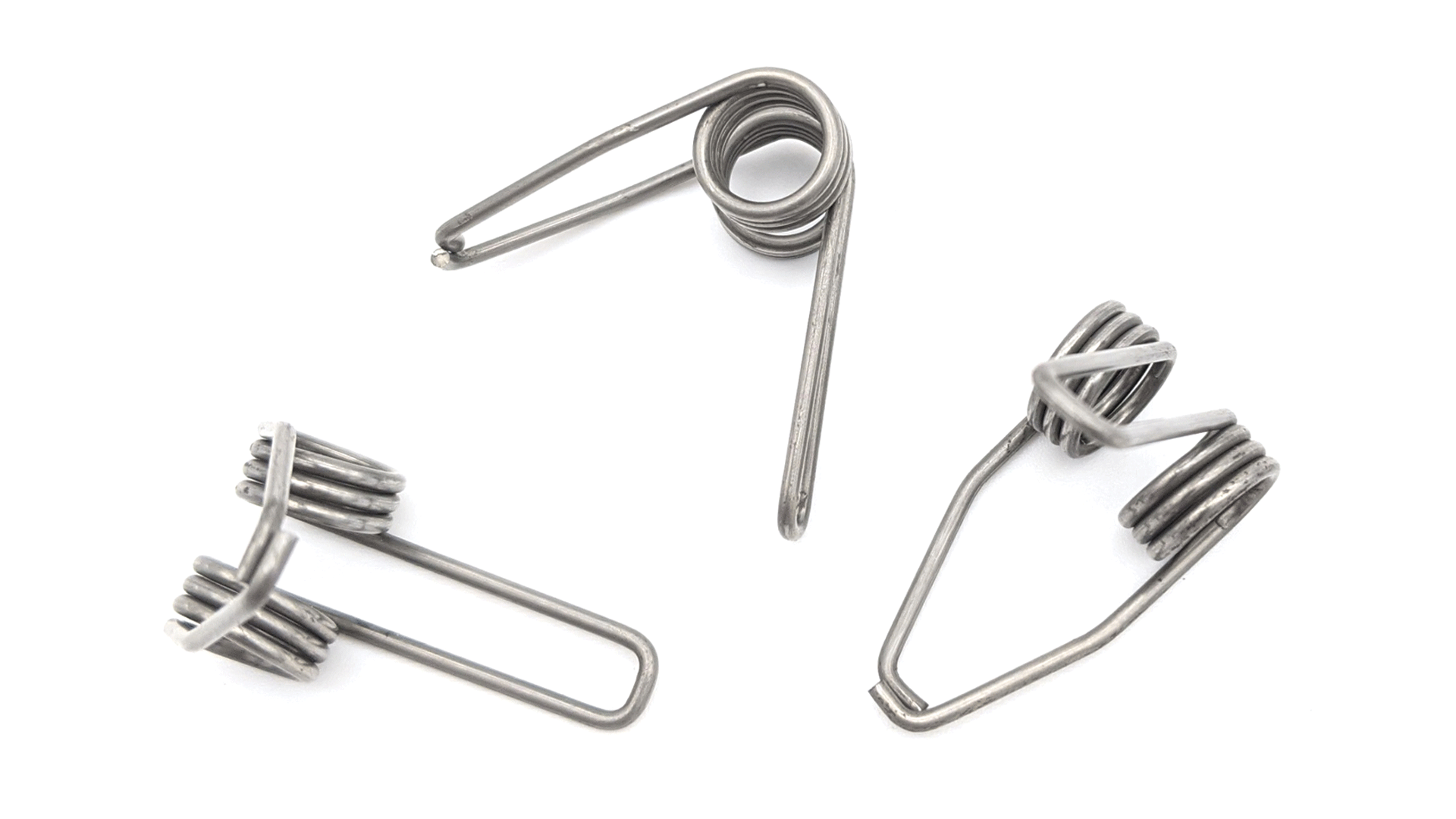

Wireform:

A wireform is a type of torsion spring that is made by bending and shaping wire into a specific configuration. It is commonly used in a wide range of applications, such as automotive, aerospace, medical devices, and consumer products.

Wireforms can be made from a variety of materials, including high-carbon steel, stainless steel, and non-ferrous metals like brass and copper. The material selection depends on the specific application and the required mechanical properties of the wireform.

Torsion springs are designed to provide a rotational force when twisted around their axis. Wireforms are often used in torsion spring applications because they are flexible, durable, and can be customized to fit specific design requirements. They can be designed with a variety of bends, angles, and loops to achieve the desired amount of torque and rotational force.

Overall, wireforms are a versatile and reliable choice for torsion spring applications, and their flexibility and customization options make them a popular choice for many different industries and applications.