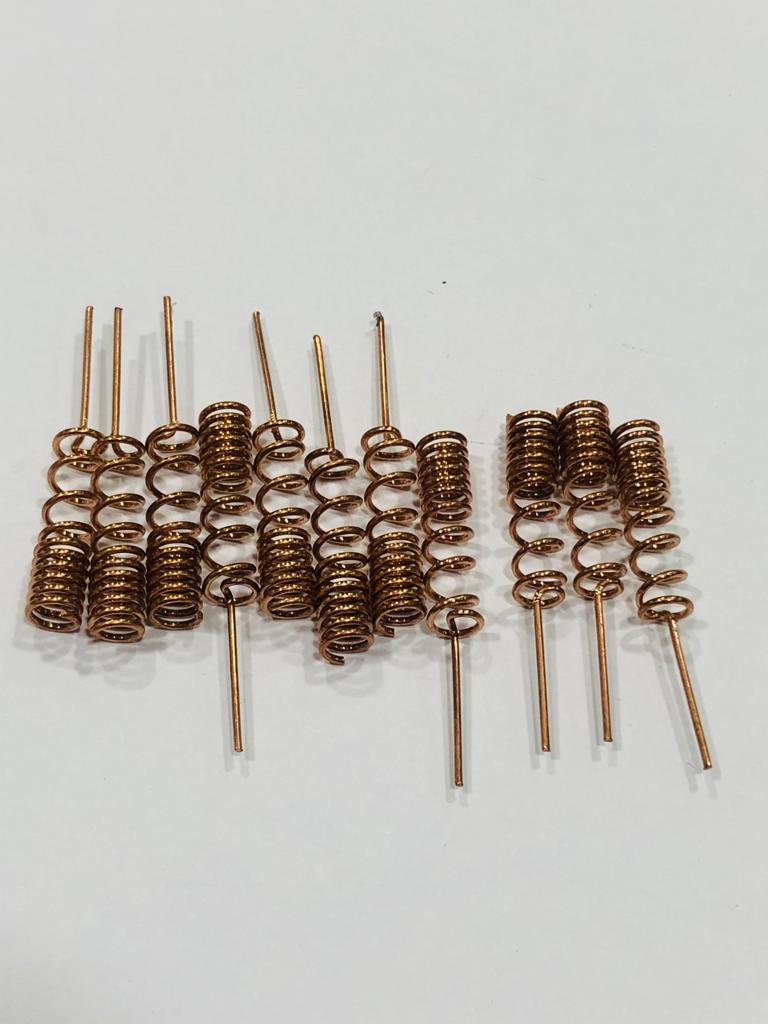

Specialized springs

Specialized springs are the ones which are made in a wire whose thickness is between 0.1mm to 25.0mm. These are the springs which can be also made up by most of the other type of materials. So these are known as special springs.

Product Description

Uses of specialized springs:

- The main motto of these springs is to handle the compressive and tensile loads.

- These springs are further classified into two types mainly,

- Compression springs and

- Tensile springs [both of them have their own applications]

- These springs are also used in medical instruments, cell phones and etc

- Lawn mowers also requires these types of specialized springs

- Major engines are also the ones which requires these types of springs